Cable Tray

Home » Our Products » Cable Tray

Cable Tray

Cable trays are utilized across a broad range of industries, including telecommunications, data centers, manufacturing, and commercial buildings. In telecommunications, they support various types of communication cables, such as fiber optics and copper lines, ensuring reliable connections. In data centers, they play a crucial role in managing the extensive cabling required for servers and networking equipment. Likewise, manufacturing facilities use cable trays to organize power and control cables for machinery, contributing to safer and more efficient operations.

One of the primary benefits of cable trays is their ability to improve organization and ease of access to wiring systems. Unlike traditional conduit systems, which can become congested and difficult to navigate, cable trays allow for a more open arrangement of cables, making it simpler for technicians to identify and troubleshoot issues. Furthermore, cable trays often promote better airflow around the cables, which helps to maintain optimal operating temperatures and extends the lifespan of the cables. They also provide flexibility, allowing for easy modifications and adjustments as the needs of the facility evolve.

a call to action

talk to us today!

Our Products

Inquiry Form

Exploring the Benefits and Applications of Cable Trays in Modern Electrical and Telecommunications Infrastructure for Effective Cable Management Solutions.

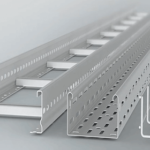

Cable trays are essential components in electrical and telecommunications infrastructure, designed to support and manage cables in various settings. They offer a structured and organized means of routing and storing electrical and data cables, making them a preferred choice in industrial, commercial, and residential applications. By providing a secure pathway for wires, cable trays not only enhance safety but also facilitate maintenance and future expansions of electrical systems.

Applications

- Electrical Power Distribution

- Telecommunications

- Data Centers

- Industrial Plants

- Building Infrastructure

- Maintenance Accessibility

- Flexibility and Scalability

- Ventilation

Available Range We are dealing in

• PRODUCT QUALITY (GRADE) •

• PLEASE FIND NICKEL ALLOYS & OTHER GRADE

• HASTELLOY: C276, C22, C2000, Hastelloy X, Hastelloy B2, Hestelloy B3.

• INCONEL: Inconel 600/601, Inconel 625, Inconel 617, inconel 686/690/693, Inconel 706/ 718, Inconel 925..YET

• INCOLOY: Incoloy 800, Incoloy 800H, Incoloy 825…YET

• MONEL: Monel 400, Monel 500…YET

• TITANIUM & TANTALUM ALLOYS: Titanium Gr-1, Titanium Gr-2, Titanium Gr-5, Titanium Gr-7, Titanium Gr- 9, Titanium Gr-12, Tantalum…YET

• DUPLEX & SUPER DUPLEX •

• Duplex 2205 (31803), Super Duplex 2507 (32750)…YET

• CUPRO NICKEL: CUNI 70:30, CUNI 90:10…YET

• ZIRCONIUM: ZR702, ZR705…YET

• STAINLESS STEEL GRADES •

• Stainless Steel : SS304/304L, SS316/316L/316TI, SS309/309L, SS310/310S ,SS303, SS347/347H, SS904/ 904L, SS409/409M , SS410/410S , SS420/430, SS201/202, SS317, SS 321..YET

• Other Grades: SMO 254, A286, Sanicro 28, 253 MA, 17-4PH / 15-5PH, Nitronic 50 / Nitronic 60, Alloy 20, Copper Beryllium C17200 Aluminium & Alloys.

• COPPER & COPPER ALLOYS •

• DHP GRADE: ASTM B 68, B 75, B 88, B 111, B 280, EN 1057, BS 2871

• ETP GRADE: IS 191, IS 2501, IS 440

Technical Specifications

| Parameter | Specifications |

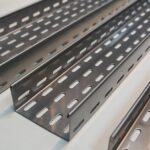

| Material | Mild Steel (Pre-Galvanized / Hot Dip Galvanized), Stainless Steel (SS304 / SS316), Aluminum |

| Tray Types | Ladder Type, Perforated Type, Solid Bottom, Wire Mesh Type |

| Width Range | 50 mm to 1000 mm |

| Height Range | 25 mm to 150 mm |

| Tray Thickness | 1.2 mm to 3.0 mm |

| Standard Length | 2500 mm (Custom lengths available on request) |

| Finish Options | Hot Dip Galvanized (HDG), Powder Coated, Pre-Galvanized, Polished (for SS) |

| Accessories | Bends (H/V), Tees, Crosses, Reducers, Couplers, Covers, Support Brackets |

| Installation Type | Indoor and Outdoor |

| Load Capacity | Light, Medium, and Heavy Duty (as per project requirement) |

| Standards Followed | IS/IEC Standards, NEMA, ASTM (as applicable) |